The trench type compost turner is the key equipment for making compost. Because of its low price and high work efficiency, it is used widely in various organic fertilizer plants.

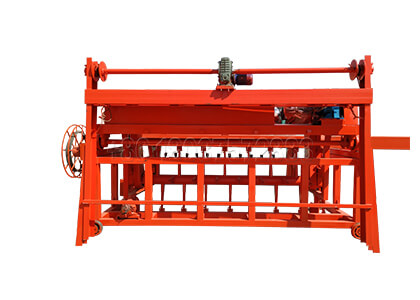

The stucture of the trench type compost turner.

And the main parts of the groove type compost making machine include: transmission device (it is an important device that provides power for turning drum), lifting device, walking device, turning device (turning teeth, roller), shifting vehicle.

Groove type Indoor Compost Machine for Sale

The vulnerable spare parts of the trench type compost machine.

In this compost making machine, the turning teeth is the vulnerable spare parts. But our turning teeth material is Manganese steel material (16 Mn). You only need change it after half or one year later. And here are some maintain methods to prolong the service life for you.

Turning Teeth of Groove type Compost Turner

How to maintain the compost turner machine?

Maintenance after work.

1. Turn off the power switch.

2. Add lubricant to each lubrication point.

3. Remove the residues and remaining materials on the machine and surrounding sites.

Weekly maintenance items.

1. Check the oil quantity of the reduction box and fill enough gear oil.

2. Remove the accumulated materials in the discharge port and keep the discharge chute unblocked.

3. Check the contact condition of each contactor in the electric control cabinet, if damaged, replace it immediately.

Regular inspection items.

1. Check the operating condition of the motor reducer, if there is abnormal noise, heat, etc.

Immediately shut down for inspection;

2. Check the wear of each bearing, if it wears too much, replace it.

In short, if you can use the compost making equipment correctly, and do some maintenance items regular, the machine will work for a long time. If you have other questions or buy compost turner machine, you can contact us, we will provide you good service.

ShunXin

ShunXin