Chicken manure management.

In the past, chicken manure management is a heavy work in the chicken farm. Usually they just pile chicken poop on the empty ground, which has an unpleasant smell and mosquitoes around it. At present, many countries have already banned the use of traditional methods to treat chicken manure. Because it pollutes environment. What method is better for chicken manure management? This method is what you will take next. You will turn chicken poop into organic fertilizer to protect environment while making money.

Turning chicken manure into organic fertilizer.

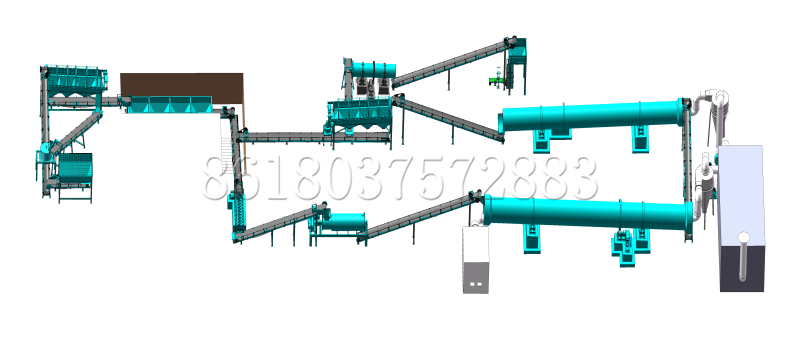

This is a best way to dispose chicken poop. With the help of SHUNXIN’s equipment, it is easy to make organic fertilizer from chicken manure. And the production process of making organic fertilizer from chicken waste includes: collecting chicken poop, composting and fermentation system, granulating system and drying and cooling, screening and packing system.

- Collecting chicken poop.

You must have raw materials before starting fertilizer business.Fermenting chicken manure.

- Composting and fermentation are the important process for chicken manure management.

The fermented chicken poop has no smell and can be used as raw materials for fertilizer. So you need to compost chicken manure. But it is convenient for you to use our fermentation compost equipment. There are many machines you can use, such as groove type compost turner, wheel type compost turner, crawler type compost turner, chain plate type compost turner and fermentation tank.

- How to make chicken manure management to earn more money?

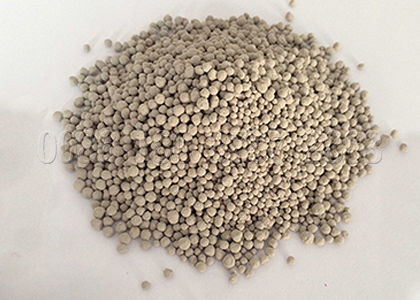

Using chicken manure compost to produce granular fertilizer is a good way to make more money. But if you want to manufacture fertilizer pellets, you need the fertilizer pelletizer machines. Now, there are many granulating machines in the market, you can choose a suitable granulator for your plant. And SHUNXIN can provide you with many types fertilizer pelletizers. They are new type organic fertilizer granulator, rotary drum churning granulator, double roller extrusion granulator, rotary drum granulator and disc granulator.

- Drying and cooling system.

In order to store or transport chicken manure fertilizer, you need rotary drying machine to dry them. Then you can use cooling machine to cool the fertilizer.

- Machine for screening chicken manure pellets.

You can use a sieving machine to sift out unqualified chicken manure fertilizer particles, and then granulate again to produce qualified products.

How many days before chicken manure become organic fertilizer?

In the process of turning chicken manure into organic fertilizer, the composting process takes the most time. Expecially, if you adopt the traditional method to compost chicken manure. It will take you 3 months or even more. If you use our composting process, it will save you a lot of time. On average, it can be fermented well which takes 10-30days.

With the continuous development of science and technology, fertilizer production has gradually become mechanized and automated. The fertilizer equipment can help you convey and turn chicken manure in chicken manure management system. And it can help you make organic fertilizer with high-efficiency. So you can use our equipment to shorten the time of turning chicken manure into organic fertilizer.

The differences between chicken manure organic fertilizer powder and granule.

Through composting and crushing, you can get powdered organic chicken manure fertilizer. Next, you have two choices, they are directly packing chicken manure organic fertilizer powder or producing granular organic fertilizer? Good chicken manure fertilizer management can also bring you more financial returns. So you should learn that differents of the powdered chicken poop organic fertilizer and granular chicken manure fertilizer, before you make a decision.

- Different production processing.

The production process of chicken manure organic fertilizer powder is simple, no granulation work is required. But the production of organic granular fertilizer has an additional granulation step on the basis of powdered organic fertilizer.

- Chicken msnure organic fertilizer pellets are more convenient to transport and use.

The chicken manure organic granular fertilizer produced by a good granulator is not easy to agglomerate, which is convenient for your storage or transportation. While The powdery organic fertilizer is not easy to store and transport for a long time, especially in bad weather.

In addtion, fertilizer particles play the role of slow release of fertilizer effectiveness. And it is convenient to apply fertilizer and is not easy to be scattered by the wind. But powdered organic fertilizer is the opposite. Therefore, except for producing powder chicken manure fertilizer according to customer requirements, most organic fertilizer manufacturers choose to produce organic granular fertilizers, when they manage chicken manure.

What should be paid attention to in the chicken manure management?

In order to better manage chicken manure and earn more profits, there are some small details in the management of chicken manure that need your attention.

- In fact, the most important thing in the chicken manure management is fermented chicken waste. The water content and temperature will affect the fermentation speed. Therefore, when you ferment chicken manure, you should control the moisture, temperature and C/N value of the compost. Moreover, the suitable moisture content for composting is 50%-60%. And the temperature should be kept at about 50℃ (if the temperature is too high, you can use a composting machine to turn chicken manure).

- In the transporting and fermenting chicken manure process, you must prevent chicken manure from polluting the air.

- When making chicken manure fertilizer pellets, you should install a dust collector after the fertilizer pelletizer. It can prevent dust from causing secondary pollution to the air.

How much does chicken manure management cost?

The cost of processing chicken manure into powdered organic fertilizer and granular organic fertilizer is different. There are two different production lines for disposing chicken manure. And the equipment of the two production lines you can find in our company.

The price of producing chicken msnure organic fertilizer powder.

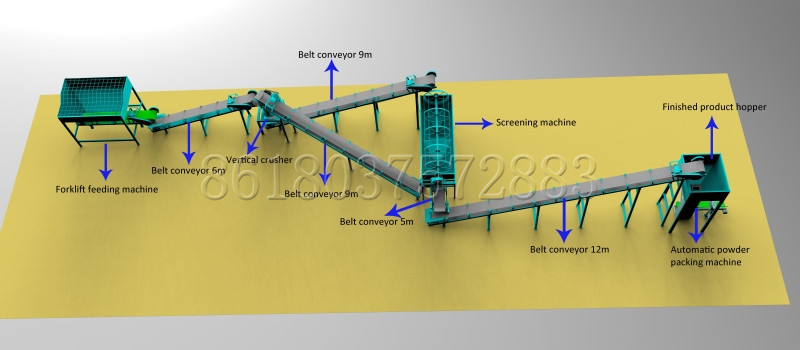

The powdered organic fertilizer production line for chicken manure management includes: fermentation compost machine, crusher and packing machine. So you need pay for these machines.

- The organic fertilizer fermentation pot price is low. If you don’t have enough place to compost chicken manure, SHUNXIN organic fertilizer fermentation pot will meet your needs. Because our organic fertilizer fermentation pot only covers an area of 10 m3-30 m3. In addition, it has the characteristic of no pollution. So you need not buy deodorizing equipment. And it is suitable for start-ups with low price.

- Long-life new type vertical crusher will cost you some money. Our new type vertical crusher will help you grind the chicken manure compost. And the important thing is that it has high crushing efficiency, and has an observation window to facilitate your observation of crushing.

Making chicken msnure fertilizer pellets cost.

The organic granular fertilizer production line for chicken manure management adds a granulation system, compared to the powder organic fertilizer production line. And you need to buy granulating equipment, drying and cooling machines (if you use double roller extrusion granulator, you need not the machines) and screening machine. In addition, you may need pay for a mixer to mix different materials, when you use chicken manure and materials to granulate organic fertilizer. If you want to buy other chicken manure granulators, you can contact us and get its price.

SX chicken manure management machines price.

And all the equipment of different scale production lines is different, the corresponding cost is also different. In addition to the equipment mentioned above, we also have a lot of cost-effective fertilizer production equipment. In addition, our equipment also supports customization to meet your different production scales. More importantly, we are direct sales by manufacturers, and the prices are all ex-factory prices. Welcome to contact us, and look forward to working with you.

ShunXin

ShunXin