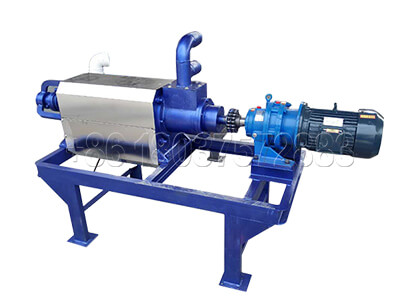

Manure separator is an auxiliary equipment for manure management. In an organic fertilizer production process, you can use it to reduce the moisture of animal maure. After dewatering, you can make compost from manure.

What is raw materials moisture before and after dewatering?

Usually, you can use the dewatering screw press machine to dispose animal manure with about 75% moisture content. And the highest feed moisture can be 80-90%. After dehydrator, you can get the organic materials with 30-40% water content. Then, if you wnat to produce organic fertilizer, you can add some fermentation bacterial to compost.

Manure Separator for Sheep Manure Dewatering in Australia

Which are the standard dimensions of the sieves’ holes?

In the dewatering machine, we equiped 0.3-0.5 mm stainless screen. And it is not easyto rust and can be used with various materials. In addition, you can tell us your requirement, and we will customized right one for you.

What method is used to send the raw materials to the dehydrator?

Our dewatering machine has feed pumps. Therefore, you can feed the animal manure into the machine through the pump easily.

How to dewater the animal manure?

Here, when you use this machine to reduce the manure (such as chicken manure, pig farm waste, cow dung and so on.)moisture, you can follow these steps:

Working Process of Dewatering Screw Press Machine

- Install the dewatering screw press machine in your fertilizer plants.

- Feed your raw materials into the equipment by feed pump.

- Start the machine to work.

- After dewatering, you need to clean the screen of this dewatering machine.

The cow dung dewatering machine price.

In SX machinery factory, we have solid-liquid separator and inclined dewatering machine for treat poultry manure. And the two machines have different capacities. Here, we take cow dung dewatering machine as an example for your reference.

Dehydrator For Reducing Raw Material Water Content

If you have a small scale organic fertilizer plant, you can buy a small solid-liquid separator with 10-15 m3, and its price about 2800 USD. But, if you want to dispose large-sized cow manure, you need buy a large machine with more cost.

ShunXin

ShunXin