What is compound fertilizer production line?

The compound fertilizer production line, as the name suggests, is used to produce the compound fertilizer. And the compound fertilizer processing line is composed of a series of advanced fertilizer equipment, which can be used for granulating all kind of compound raw materials. If you want to make compound fertilizer with different concentrations. There are 3 main types of compound fertilizer production lines for you that SHUNXIN heavy industry provided. They are NPK fertilizer production line, Urea fertilizer making line and BB fertilizer production line. In addition, other fertilizer processing lines that you would like to learn, you can contact us now.

3 types of compound fertilizer production lines for sale.

How to make NPK fertilizer?

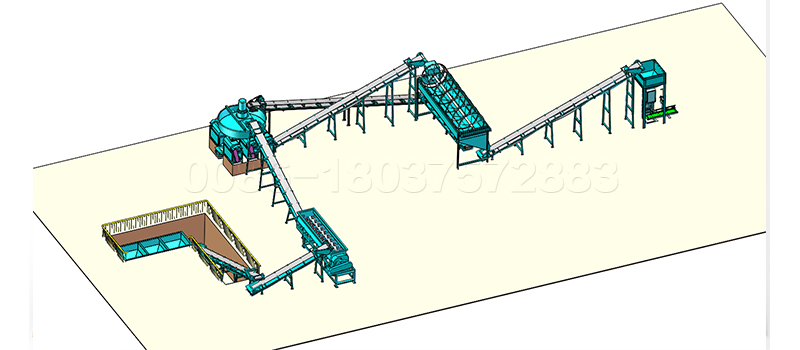

NPK fertilizer is rich in nitrogen, phosphorus and potassium, and is currently a widely used fertilizer. There are powdered and granular NPK fertilizer, but most producers will choose to produce granular NPK fertilizer. Because granule is easy to store and transport, and its fertilizer efficiency is stable. And the key equipment for producing NPK granule is a granulator. There are two ways of dry type granulation and wet type granulation for you to choose. We can provide you with a double roller extrusion granulator, if you like to use the dry granulation process. We also have pan granulator and rotary drum granulator, which are suitable for wet granulation.

What is BB compound fertilizer production line?

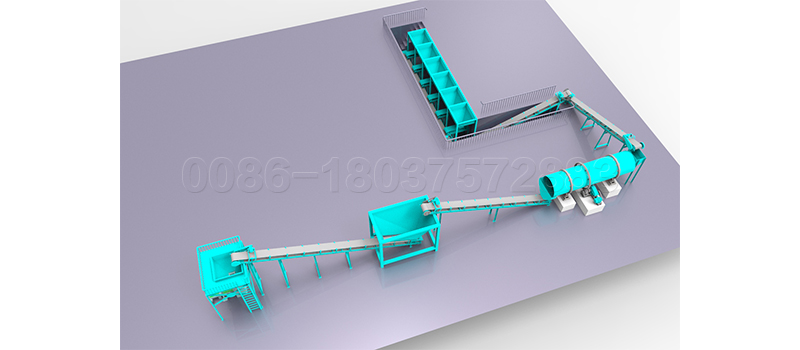

The blended fertilizer has several single fertilizers with relatively consistent granular shapes, mainly containing nitrogen, phosphorus and potassium. The simplest preparation method of BB fertilizer is to mix the raw materials in a machine according to a certain proportion. Therefore, you can use our drum type BB fertilizer mixer to blend the materials evenly, then pack them into bags. If you have a static parallel batching machine in your fertilizer company, it will help you save the production time and costs.

Other compound fertilizer production line in SX.

Are there other fertilizer production lines? Of course, there are many types of production lines in our company. We have large-scale compound fertilizer production lines, production lines with different raw materials. For example, physical pelletizing for making urea compound fertilizer. What’s more, our company can customize production lines and equipment according to your needs.

What are raw materials for compound fertilizer production?

The raw materials of compound fertilizer are substances rich in nitrogen, phosphorus and potassium, so we can divide the raw materials of compound fertilizer into the following three categories.

- Raw materials containing nitrogen. Ammonium bicarbonate, ammonium sulfate, ammonium nitrate, calcium nitrate, urea, calcium nitrate, etc.

- Phosphorus source material. Superphosphate, ammonium phosphate, tricalcium phosphate, dicalcium phosphate and so on.

- Potash raw materials. Potassium chloride, potassium sulfate, potassium carbonate, potassium magnesium fertilizer, plant ash, etc.

In short, the compound fertilizer production line has wide adaptability to raw materials, and you can use it to get more economic benefits. If you want to determine whether our production line equipment is suitable for your raw materials, you can bring raw materials to our company for testing.

How to make high-quality fertilizer using compound fertilizer production line?

For all compound fertilizer manufacturers, producing high-quality compound fertilizer is the most important. If you are a new comer in the compound fertilizer industry, you must first know the compound fertilizer production process. And then, you have to think about how to produce high-quality compound fertilizer.

2 suggestions can help you produce high quality compound fertilizer.

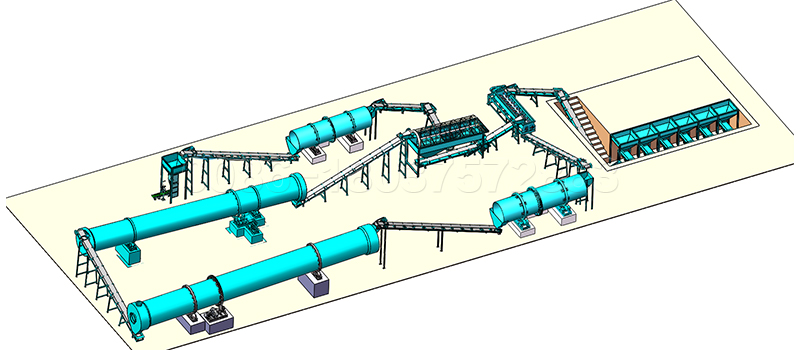

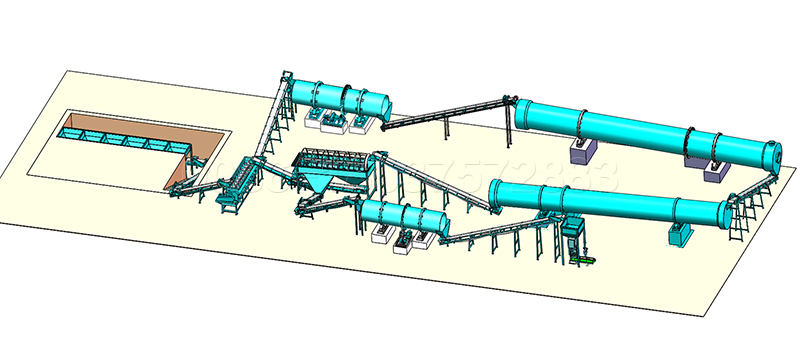

- Firstly, in order to get high-quality fertilizer, you should use good compound fertilizer production line. And the compound fertilizer production lines include the following machines: dynamic automatic batching system, fertilizer mixing machine, fertilizer crushing machine, rotary drum granulator, rotary drum drying machine, rotary drum coating machine, rotary screening machine, packaging machine, belt conveyor and other accessories.

- Then, for producing high-quality compound fertilizer, you should pay attention to the quality of the product in every production process. The compound fertilizer production process usually includes: batching system, granulation system and post-processing system. Therefore, you should use high-quality raw materials. And you need to strictly control the temperature and moisture in the production process. In addition, you can use our fertilizer polishing machine, which can help you achieve the more beautiful compound fertilizer.

If you have other questions about compound fertilizer production lines, you can ask us. Our professional salesperson will help you solve your questions and give you help in your fertilizer manufacturing business.

How to become a compound fertilizer manufacturer?

For those who are new to the compound fertilizer industry, we recommend that you start with a small-scale compound fertilizer plant. Before becoming a small-scale compound fertilizer manufacture, you need to do following things.

- First of all, you should investigate the development of the compound fertilizer industry and make your business plan. Write down your budget for building a small compound fertilizer plant and your expected annual output in your business plan.

- Then you have to determine your raw materials, plant location, compound fertilizer production line, workers and other things for your small-scale compound fertilizer factory. These all are the necessary conditions for the establishment of a compound fertilizer plant.

- Finally, you had better cooperate with an experienced fertilizer equipment manufacturer, such as SHUNXIN. Because an experienced fertilizer equipment manufacturer will help you design a fertilizer production line that suits you, and will provide you with necessary assistance during your fertilizer production process.

Why choose the compound fertilizer production line in SHUNXIN?

When you choose a compound fertilizer production line, what do you care most about? For all compound fertilizer manufactures who choose SHUNXIN’s compound fertilizer processing lines, our fertilizer making lines can meet your needs and bring you considerable profit. Here are some features of our compound fertilizer production line to help you understand our production line.

Features of SX compound fertilizer production line.

- Compact layout and high-quality equipment. The complete set of equipment layout is designed compactly. And we all use advanced technology to designe fertilizer machines. They not only run smoothly with low energy consumption, but also have good economic returns.

- Wide adaptability of raw materials. You can use the processing line to compound fertilizer with various kind of raw materials.

- High compound fertilizer yield. You can use our production line to produce different concentrations of compound fertilizer according the ratio of raw materials.

- Low-cost. All fertilizer machines are manufactured and sold by our own. So, you can buy our fertilizer equipment at the ex-factory price.

- Considerate after-sales service. Having considerate after-sales service is improtant. For example, if you purchase our fertilizer machines, we can help you solve the problem of machine operator training or later machine maintenance problems.

If you would like to know more about us, you can contact us now.

ShunXin

ShunXin